Introduction

This article delves into the innovative technology of Self-Healing Paint Protection Film (PPF), examining the material science behind its reparative capabilities. We explore how elastomeric polymers in Clear Paint Protection Film enable autonomous mending of minor abrasions, discuss activation mechanisms, tangible benefits, and inherent limitations of this advanced automotive shield, underscoring its value in maintaining long-term aesthetic integrity.

Detecting A Self -Healing Paint Protection Film: Mechanism, Efficiency and Benefits

The development of protection against the automotive industry has led to remarkable innovations, among which is a self -delayed film protection film (PPF) excels as a particularly sophisticated solution. This technology directly deals with the persistent problem of minor aesthetic damage that vehicles inevitably obtain during everyday use. This article will deconstruct the concept of Self-Healing PPF, elucidate its operational principles from a scientific standpoint, and assess its practical benefits for vehicle owners seeking to maintain optimal surface integrity and appearance.

1. Defining Self-Healing Paint Protection Film Technology

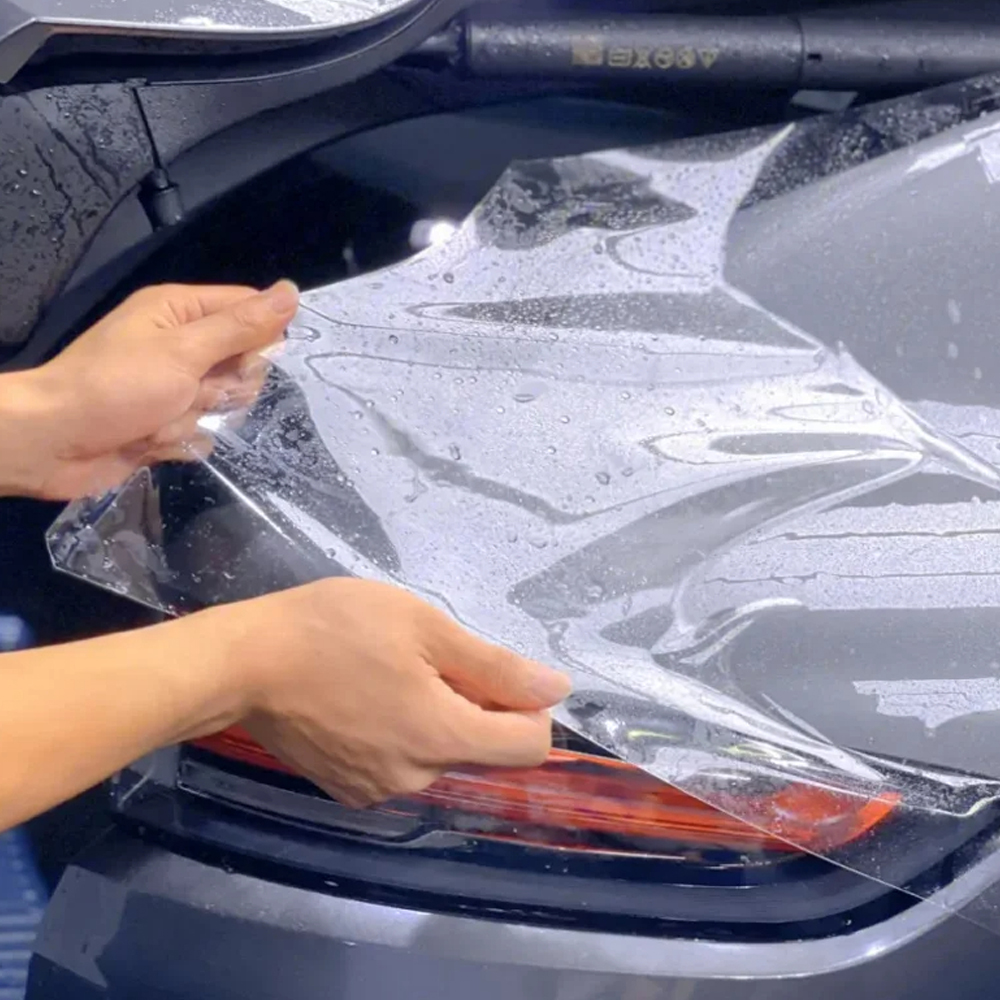

The self -winging film about color protection is an advanced iteration of traditional PPF. It is a multilayer polymer laminate specifically designed not only to protect the painted surfaces of the vehicle from typical forms of minor damage-as light scratches, beliefs of washing, insect etching, and small spout-buttons are also autonomously repaired by these surface imperfections. The defining characteristic of this technology is its inherent ability, often accelerated by thermal energy, to return its upper surface to a smooth, undamaged state. This results in a permanent high -gloss finish and significantly reduce the need for frequent polishing or specialized correction procedures.

2. Scientific Mechanism: Elastomeric Polymers and Thermal Activation

The ability of modern colors to protect colors is rooted in the material science of their highest layer. This layer is usually a specialized thermoplastic polyurethane (TPU), which includes an elastomeric polymeric top coat. The mechanism functions as follows:

- Elastomeric properties: Elastomers are polymers that show both viscosity (resistance to flow under stress) and elasticity (the ability to return to their original shape after deformation). The polymer chains in this top layer are decent in the specific network structure that transmits the material “shape memory”.

- Viscoellastic flow: When there is a small scratch or abrasion on the surface of the self -healing PPF, the polymeric chains in the immediate vicinity are moved or temporarily deformed. The application of heat reduces the viscosity of the material and increases the kinetic energy and mobility of these polymeric chains. This allows them to flow, separate and reorganize, effectively “fill” the depression of scratches and restore a smooth, flat surface.

- Thermal activation: While to a certain minimum degree of self -healing could occur at higher ambient temperatures for a longer period of time, the process is significantly accelerated and streamlined by direct or indirect thermal energy application. This energy provides the necessary impulse (activation energy) for polymeric chains to overcome intermolecular forces and effectively regrouping. Normal heat sources include: 3.1 Solar radiation (natural sunlight) 3.2 Warm water (e.g., poured over the affected area or during a warm vehicle wash) 3.3 Ambient heat from the engine radiating to filmed surfaces like the hood 3.4 A controlled application of warm air from a heat gun or hairdryer used on a low, safe setting.

3. The Chemistry Behind the Cure: A Closer Look at Thermoplastic Polyurethanes in Self-Healing PPF

The remarkable properties of Self-Healing PPF are largely attributable to the sophisticated chemistry of Thermoplastic Polyurethanes (TPUs) used in their construction, especially in the self-healing topcoat. TPUs are a class of block copolymers, meaning they are composed of alternating sequences of “hard” and “soft” segments at a molecular level:

- Hard segments: These segments are usually formed by disocyanates and short chain diols. They contribute significantly to the overall strength of the material, abrasion resistance, chemical resistance and thermal stability. These hard segments can be arranged in arranged, sometimes crystalline domains through strong intermolecular forces, such as a hydrogen bond acting as a physical intensification that gives the material its toughness.

- Soft Segments: These are usually derived from long-chain polyols (such as polyesters or polyethers). They are responsible for the TPU’s flexibility, elasticity, impact absorption, and good performance at low temperatures. These amorphous segments provide the elastomeric character.

The self-healing capability often arises from the dynamic nature of the bonds within the TPU network (especially in the specialized topcoat) or the ability of the amorphous soft segments to reflow when energized. When the material is scratched, molecular chains are displaced. Heat provides the energy for these soft segments to regain mobility, allowing chains to disentangle, re-align, and for any temporarily disrupted physical crosslinks to reform. This allows the material to relax back into its original, lower-energy (smoother) state, thus “erasing” the scratch. The precise formulation of these hard and soft segments, their ratio, molecular weight, and the inclusion of proprietary additives in the topcoat, dictate the efficiency, speed, and temperature requirements of the self-healing process for a particular Paint Protection Film product.

- Validating the “Self-Healing” Claim: Efficacy and Inherent Limitations

The self-healing attribute of modern, high-quality Self-Healing Paint Protection Films is a scientifically demonstrable phenomenon and highly effective within its designed parameters for maintaining a pristine surface.

- Effective extent of repair: self -healing is the best known in correcting surface damage, which is limited to the elastomeric top coat of the film. This usually includes light scratches from nails, desperate brushes for car washing, small abrasions from everyday use, and especially a fine network of microrobins known as beliefs.

- Inherent restrictions: It is essential for users to understand that self -healing PPF is not an infallible panacea for all types of damage. Its reparative capabilities do not extend to:

- Deep Scratches or Gouges: Damage that penetrates through the self-healing topcoat and into the main polyurethane base layer of the film, or worse, through the film to the vehicle’s paint itself, is beyond its self-healing capacity.

- Impacts Causing Punctures or Tears: Significant impacts from road debris like sharp stones that puncture or tear the Paint Protection Film will not self-repair. In such cases, the film will still have served its primary purpose of protecting the underlying paint from the initial impact, but the film itself will exhibit the damage and may require sectional replacement.

- Severe Chemical Etching or Staining: While highly resistant to many common automotive chemicals, prolonged exposure to aggressive solvents or highly acidic/alkaline substances might permanently alter or stain the topcoat beyond its ability to self-heal.

Self-Healing PPF vs. Standard Non-Healing PPF

| Feature | Standard Non-Healing Paint Protection Film | Premium Self-Healing Paint Protection Film |

|---|---|---|

| Primary Material Composition | Thermoplastic Polyurethane (TPU) | TPU with Specialized Elastomeric Topcoat |

| Minor Scratch Repair | No inherent repair capability | Yes, via thermal activation (e.g., heat from sun, warm water) |

| Swirl Mark Resistance | Relies solely on initial scratch resistance | Actively repairs and eliminates most swirl marks |

| Maintenance of Gloss/Clarity | Prone to accumulating micro-scratches over time, which can dull the finish | Maintains higher gloss & clarity for a longer duration due to self-repair of minor blemishes |

| Typical Warranted Lifespan | Often 5-7 years (can vary by brand/product) | Often 7-10+ years (can vary, premium lines generally offer longer warranties) |

| Relative Cost | Generally Lower | Generally Higher |

| Key Aesthetic Benefit | Good impact & basic scratch protection | Superior long-term aesthetic appearance & reduced need for paint polishing |

5. Tangible Advantages of Investing in Self-Healing PPF

The selection of high -quality self -healing film protection film offers several convincing benefits for vehicle owners, which are devoted to maintaining the appearance of the showroom of their vehicle and long -term value:

- Reduced Maintenance Stress: Autonomous Repair of Small Scratches and Filming significantly reduces the need for frequent corrective polishing or specialized interventions of details, saving the time of the owner, effort and expenditure.

- Permanent aesthetic attraction: The self -solving PPF continuously ensures that the vehicle retains “only detailed” high gloss and optically clear surface for a much longer period compared to unprotected paint or standard, untreated films.

- Comprehensive color protection: In addition to its unique self -healing capabilities, it provides a robust physical barrier against more significant threats such as stone chips, insect acids, bird droppings, road tar, tree and other environmental contaminants that can better glue or damage basic factories.

- Potential maintaining the value of further sales: a vehicle that constantly shows untouched painting, without normal minor damage to everyday driving, tends to be more attractive for potential buyers and can control the higher value of additional sales.

6. Optimizing Longevity: Care and Maintenance for Self-Healing PPF

While self -healing color protection film is designed for relatively low maintenance, adherence to certain nursing procedures ensures its optimal performance and maximizes its functional life:

- Regular fine washing: Clean the vehicle with pH-neutral and soft, non-free dishwashers or microfibre towels. This prevents the accumulation of abrasive impurities and contaminants that could defend the self -healing process over time, or, if it is gross enough, causes scratches for the threshold of the film healing.

- Avoiding hard chemicals and abrasives: delay in the use of aggressive chemical cleaners, strong solvents, pellers that are not assessed safe for PPF or abrasive shine/compounds. These substances can damage the elastomeric top coat and a compromise or permanently destroy its self -healing properties.

- Facing the healing process (if necessary): while most healing is passive (eg from exposure to the sun during normal use), if the light scratches appear and faster healing is required, gently pouring warm (not boiling 120-140 ° F or 50-60 ° C) or by low to medium thermal (6-12 inch) Up to medium-high distance (6-12 inches) (6-12 inches), which is possible to the market (6-12 inches), on the lowest area (6-12 inches) (6-140 ° C), which is low to accompaniment (6-120 ° C) from low to low heat (6-140 ° F). process. Always consult specific instructions of the PPF manufacturer for their recommendations on the application of heat.

- Consideration of compatible top coatings: Some automotive ceramic coatings are specially formulated to compatible with self -healing PPF. The use of such a coating can add another layer of hydrophobicity (water repetition), increased chemical resistance and easy cleaning, potentially without significantly preventing the film healing mechanism. However, it is essential to verify compatibility with PPF manufacturers and coating.

Conclusion

The self -winging film on color protection is significant technological progress in the automotive industry. Its remarkable ability to repair minor scratches and beliefs, which is a performance rooted in a sophisticated material science of elastomeric polymers and their reaction to thermal activation, offers unbeatable advantages in maintaining the aesthetic perfection of the vehicle with relatively reduced maintenance. Although this is not impermeable for all forms of damage, advanced protective and regenerative properties of high -quality self -healing PPF make it a reasonable and valuable investment for demanding vehicle owners looking for long -term maintenance of the intact ending of their car against strictness. Understanding his abilities, restrictions and proper care ensures that this innovative shield fulfills its promise for the coming years.