Introduction

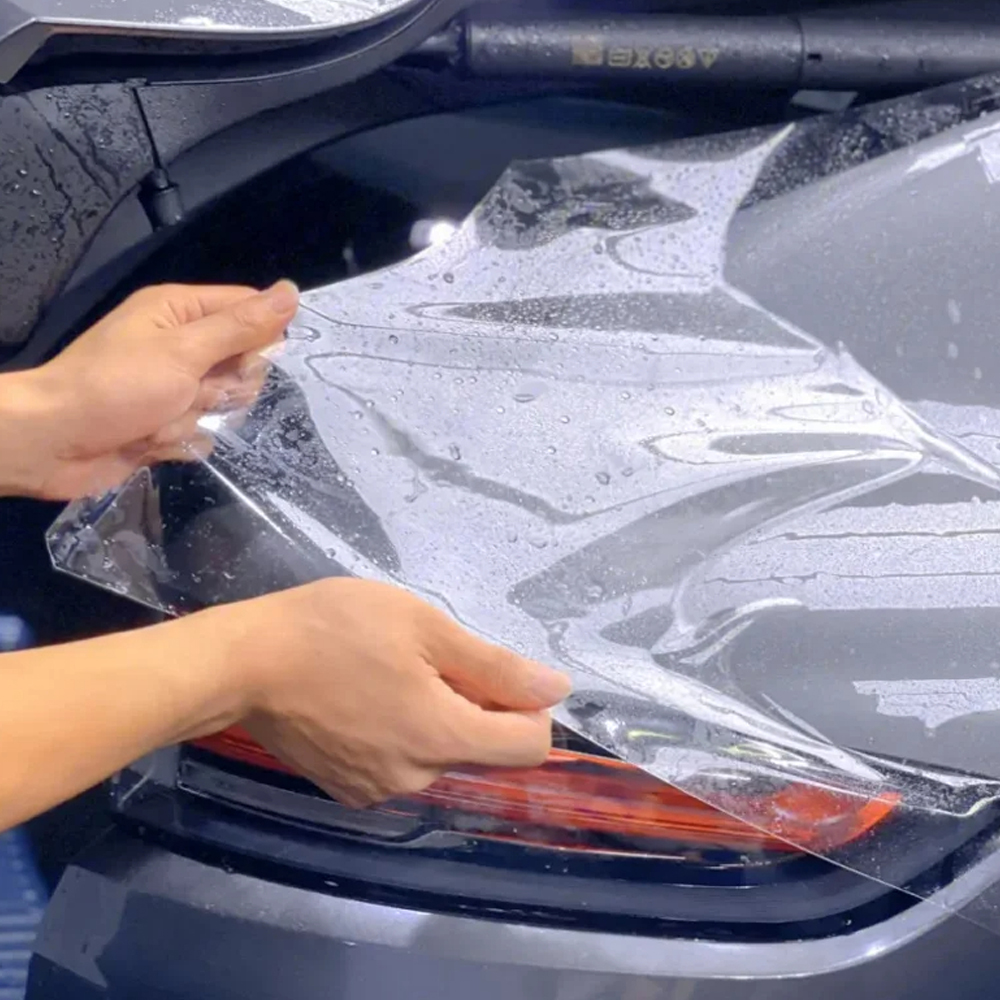

This article offers a scientific examination of the durability and performance of Paint Protection Films (PPF), particularly Clear Paint Protection Film, when subjected to diverse and extreme weather phenomena. We analyze UV radiation mechanisms, temperature extremes, precipitation and physical aggressors such as hail and road salt for PPF integrity. The discussion also emphasizes considerations about material science, technological progress and basic mitigation strategies that maximize the life and protective efficiency of these advanced polymer shields in harsh environmental conditions.

Paint Protection Film Under Siege: Analyzing Durability in Extreme Climates

The resistance of the vehicle’s protective measures is often most critically tested when it is confronted by the toughest conditions of nature. For the owners who invested in the film to protect against colors (PPF), the significant question of its perseverance against the tireless sun, frost or violent storms is important. This analysis immerses in scientific and material aspects that modify, how modern color protection films, especially pure color protection film, resist and respond to the onslaught of extreme weather and what measures can maintain their integrity.

1. The Onslaught of Weather: How Elements Challenge Paint Protection Film

Paint Protection Films are engineered to be robust, but they are not impervious to the cumulative stress imposed by severe environmental factors.

Impact of Precipitation and Physical Aggressors

Hailstorms represent a significant mechanical threat, capable of denting the underlying metal and potentially breaching or marring the PPF itself. While the film acts as a sacrificial layer, absorbing much of the impact energy, repeated or severe hail can compromise it. Similarly, heavy rain and snow introduce sustained moisture. While high -quality PPF adhesives are highly resistant to water, extended exposure, especially if the edges are not perfectly sealed or if the film is already at risk, can potentially lead to moisture, weakening adhesive bond and increasing the susceptibility to bubbling or peeling over time. In addition, in regions using road salt for alienation, these corrosive agents carry. If it is not regularly cleaned, salt can accumulate and chemically degrade the surface and adhesive layer of the film.

The Degrading Force of UV Radiation on Paint Protection Film

Ultraviolet (UV) radiation from direct sunlight is a persistent adversary for polymeric materials, including the thermoplastic polyurethane (TPU) commonly used in high-quality Paint Protection Films. Prolonged UV exposure initiates photodegradation processes within the film, which can manifest as:

- Margins: A common problem with older or lower quality films, although premium clear color protection movies now include advanced UV inhibitors to significantly resist it.

- BritTeness: UV radiation can decompose polymer chains, reduce the flexibility of the film and increase it susceptible to cracking or tearing.

- Reduced clarity: The film can become a vague and reduce its optical transparency and aesthetic attraction of the underlying color. High-performance Paint Protection Films are engineered with UV-resistant topcoats and stabilizers that can block a very high percentage (often quoted up to 99%) of harmful UV rays, substantially extending the film’s resistance to these effects.

Thermal Extremes: The Dual Challenge of Heat and Cold

Temperature fluctuations exert considerable stress on PPF:

- Extreme Heat: High ambient temperatures, or direct solar heating of dark-colored vehicles, can cause the PPF to soften. In this state, it becomes more pliable but also more susceptible to imprinting from minor impacts or pressure. The prolonged heat can also accelerate the aging of the adhesive, which potentially leads to a reduction in the strength of the binding and lifting the edges, especially if the film is under tension around complex curves.

- Extreme cold: On the other hand, very low temperatures cause PPF material to become stricter and less elastic. Thanks to this increased stiffness, it is more vulnerable for cracking or tearing, especially if it is subjected to impacts or bending. Fast and frequent temperature cycling (daily temperature fluctuations) causes repeated expansion and contraction of the film and the vehicle body panels. While PPF is designed to accommodate some thermal movement, excessive cycling can stress the adhesive bond and the film itself over its lifespan.

2. Material Science and Manufacturing: The Core of Weather Resistance

The inherent ability of a Paint Protection Film to withstand extreme weather is fundamentally tied to its material composition and manufacturing quality.

- Quality dictates durability: front color protection signs invest considerable amounts in research and development to produce multilayer movies. These often feature:

- Robust, optically pure thermoplastic polyurethane (TPU) for absorption and flexibility of impact.

- Advanced, top top coat, providing chemical resistance, scratch resistance (often with self -healing properties) and key UV protection.

- Durable, pressure -sensitive adhesive formulated for strong bonds in a wide temperature range and moisture resistance. On the other hand, lower quality films can use lower TPU classes, less effective UV inhibitors or less stable adhesives, leading to significantly faster degradation (eg premature yellowing, cracking, peeling, loss of transparency) when exposed to harsh conditions.

3. Innovations in Weather-Resistant Paint Protection Film Technologies

The PPF industry continually evolves, with manufacturers striving to enhance film durability against environmental stressors. Key advancements include:

- Nanotechnology in Topcoats: Some premium films for color protection incorporate nanoparticles into their top coats. This can create a denser, hydrophobic (water-adhesive) surface and improve resistance to dyeing from water spots, acid rain and other contaminants. It can also increase scratch and MAR resistance.

- Advanced packages of UV inhibitors: UV stabilizers are constantly refined. Modern films use synergistic mixtures of inhibitors that provide wider UV radiation protection and longer efficiency, which significantly delay yellowing and degradation of material.

- Improved adhesive formulations: adhesives develop with improved thermal stability, which means that they maintain their strength more efficiently in a wider temperature range, reducing the risk of the edge lift at extreme heat or cooling in cold.

- Specific product lines for rough climates: Some manufacturers offer specific PPF product lines designed by thicker layers or specialized top channels explicitly designed for regions with exceptionally high exposure to UV, extreme temperatures or abrasive conditions.

Table: Weather Impact on PPF and Mitigation Strategies

| Weather Condition | Primary Effect on Paint Protection Film (PPF) | Mitigation Strategy / Film Characteristic |

|---|---|---|

| Intense UV Radiation | Yellowing, brittleness, reduced clarity, topcoat degradation. | Choose high-quality Clear Paint Protection Film with advanced UV inhibitors; park in shade; use car covers. |

| Extreme Heat | Softening (increased vulnerability), adhesive weakening, potential edge lift. | Select films with high thermal stability; avoid prolonged direct sun on dark surfaces; ensure quality installation. |

| Extreme Cold | Increased stiffness, higher risk of cracking/tearing upon impact. | Opt for flexible, high-grade TPU films; avoid impacts in extreme cold. |

| Hail / Debris Impact | Dents (on panel), film tearing, punctures, significant abrasion. | Thicker PPF offers more protection; self-healing topcoats can repair minor marks. |

| Heavy Rain/Snow | Moisture ingress (if edges compromised), potential adhesive weakening. | Ensure professional installation with sealed edges; regular cleaning to remove standing water/contaminants. |

| Road Salt/Chemicals | Chemical degradation of film and adhesive, staining. | Frequent washing with pH-neutral soap, especially in winter; consider PPF-specific sealants. |

4. Maximizing Longevity: Maintenance and Proactive Care in Adverse Conditions

While material quality is foundational, the long-term performance of Paint Protection Film in extreme weather heavily depends on proper installation and diligent maintenance.

- Installation quality: Professional and careful installation is paramount. This ensures that the edges are properly packed or sealed, minimize the input points for humidity and contaminants and that the film is applied without unnecessary tension.

- Regular inspection: Especially during or after extreme weather or for a period of visually check PPF to see if there are signs of lifting, bubbling, tears or coloring. Immediate solutions of minor problems can prevent escalation.

- Suitable cleaning: Regular washing with pH-neutral car shampoos and soft strands is essential for removing abrasive residues, corrosive salts, bird droppings and other contaminants than they can damage the film. Avoid harsh chemical cleaners or abrasive brushes.

- Control habits and exposures: Although not always controllable, they minimize exposure by parking in garages or shaded areas and carefully riding on roads with heavy residues can reduce the wear of the film.

High quality color protection films, with proper care, can usually take 5-7 years, and some premium options with warranty are up to 10 years or more, even under slightly unfavorable conditions. In constantly extreme environments, however, there may be a lifetime at the lower end of these ranges or even shorter for lower quality films.

High-quality Paint Protection Films, with proper care, can typically last 5-7 years, and some premium options with warranties extend up to 10 years or more, even in moderately adverse conditions. However, in persistently extreme environments, lifespans may be at the lower end of these ranges, or even shorter for inferior quality films.

Conclusion

Extreme weather conditions undeniably represent an impressive challenge for the durability of color protection films. UV radiation, thermal tension, humidity and physical impacts contribute to the gradual degradation of these protective layers. However, the extent of this impact is significantly mediated by the internal quality of the clear film protection, the accuracy of its installation and the consistency of the owner’s maintenance. Modern advances in PPF technology have brought remarkable resistance films. By selecting high -quality products, providing professional applications and adherence to recommended nursing procedures, vehicle owners can significantly extend the effective lifetime of their color to protection against and protect their automotive investments against even the most demanding elementary forces.