Abstract

Investing in a film to protect against the colors of cars (PPF) is an important decision to maintain aesthetics and the value of the vehicle. This article immerses into the scientific basics of modern color protection film, exploring its typical life, key factors affecting its longevity and technological advances that define its protective properties. Our goal is to provide a clear understanding of evidence -based, reveal common myths, and seize vehicle owners to inform about the application and maintenance of film movies for vehicle protection.

Efforts to maintain an untouched demonstration room of the vehicle leads many owners to consider the film to protect against colors (PPF). The primary question arises: How long does this protective layer really last? In general, a high -quality film protection film can offer robust protection for 5 to 10 years. However, this lifetime is not absolute and is conditioned by the confluence of the variables, including the science of material, the quality of the installation, environmental stressors and careful maintenance.

Factors Influencing Vehicle Paint Protection Film Durability

The operational lifespan of any vehicle paint protection film is influenced by several key determinants:

- Material Composition & Quality: Premium films, typically composed of Thermoplastic Polyurethane (TPU), offer superior elasticity, UV resistance, and self-healing properties, contributing to extended durability.

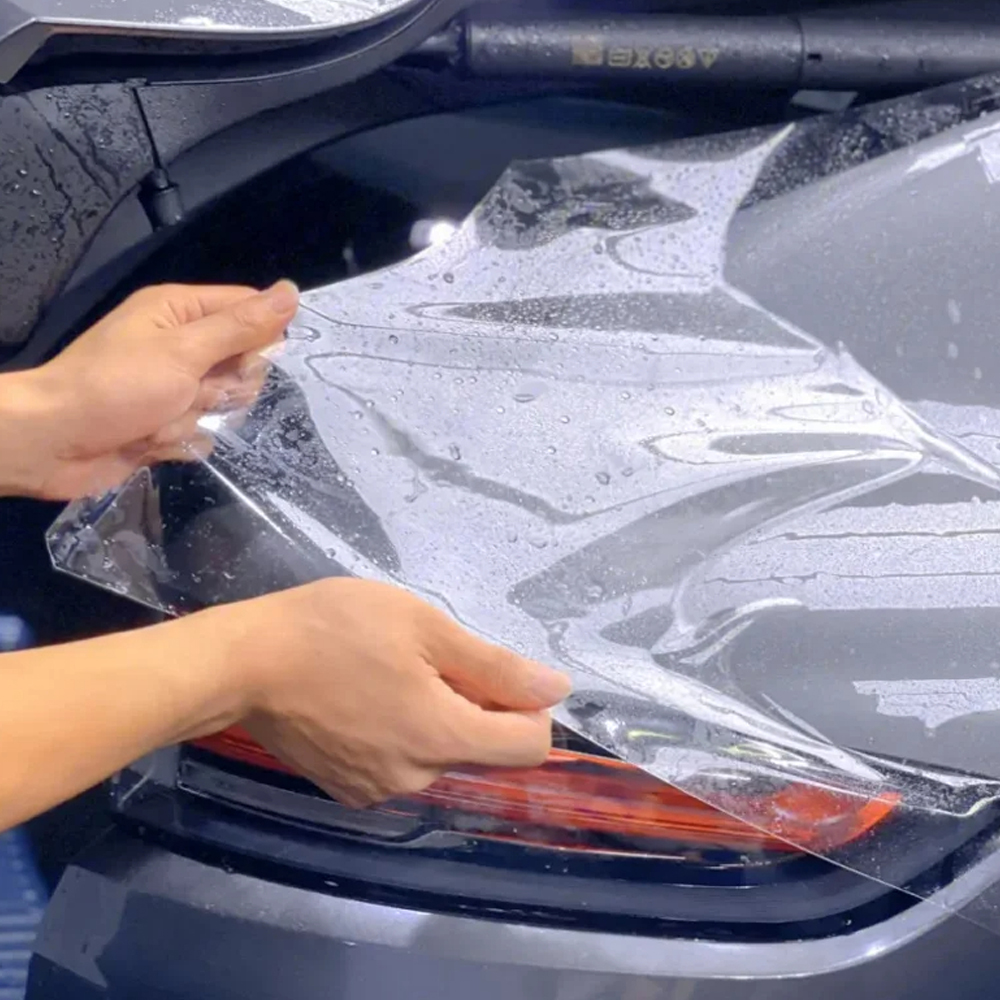

- Installation Precision: The expertise of the installer is paramount. Flawless application, ensuring full adhesion without contaminants or stress points, prevents premature failure like peeling or bubbling.

- Environmental Exposure: Prolonged exposure to intense solar radiation (UV rays), extreme temperature fluctuations, atmospheric pollutants (e.g., acid rain, industrial fallout), and abrasive elements (e.g., road salt, bird droppings) can accelerate the degradation of the paint protection film.

- Driving Conditions & Mechanical Stress: Frequent operation on unpaved roads, in construction zones, or high-velocity driving can subject the film to increased impacts from gravel and debris, leading to accelerated wear.

- Maintenance Regimen: Regular, gentle cleaning using pH-neutral soaps and avoiding abrasive tools or harsh chemicals can significantly prolong the film’s clarity and integrity. Some owners opt for additional ceramic coatings over the PPF for enhanced hydrophobicity and ease of cleaning.

Recognizing Degradation in Car Paint Protection Film

Even the most advanced car paint protection film will exhibit signs of aging over time:

- Discoloration (Yellowing/Hazing): Primarily an issue with older or lower-quality films, UV degradation can cause a yellowish or cloudy appearance.

- Adhesion Failure (Bubbling/Peeling): Loss of adhesion, often starting at edges or around complex curves, indicates film or adhesive breakdown.

- Surface Imperfections: While designed to absorb impacts, an accumulation of deep scratches or pitting beyond the film’s self-healing capacity signifies wear.

- Edge Lifting: The film’s perimeter may begin to detach or curl upwards, compromising the seal and allowing contaminants underneath.

Understanding PPF Technology: Materials and Mechanisms

Modern paint protection film is a marvel of polymer science, predominantly utilizing Thermoplastic Polyurethane (TPU). TPU is chosen for its exceptional properties:

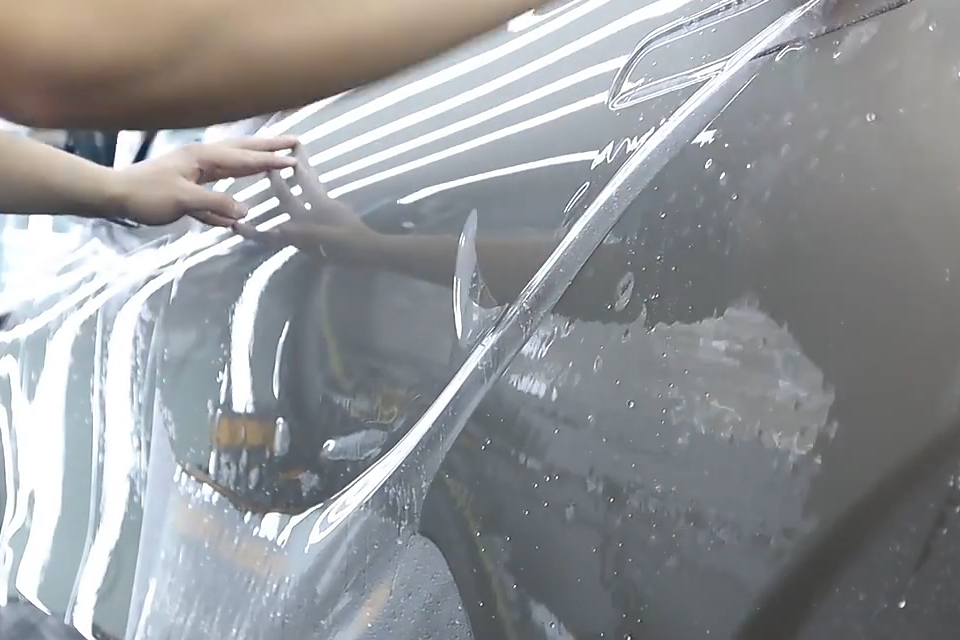

- Elasticity and Conformability: TPU can be stretched significantly without tearing, allowing it to conform to complex vehicle contours.

- Impact Resistance: It possesses high tensile strength and tear resistance, absorbing the energy from small stones and debris.

- Optical Clarity: High-grade TPUs are virtually invisible once applied, preserving the original paint color and gloss.

- Chemical Resistance: It offers a barrier against many common automotive chemicals, bird droppings, and bug splatter.

A key innovation in premium vehicle paint protection film is its self-healing capability. This is typically achieved through an elastomeric polymer topcoat. When minor scratches occur (e.g., from car washes or light abrasions), the heat from the sun, engine, or even warm water allows these polymers to reflow and fill the imperfections, restoring a smooth surface. This is not a perpetual process, and deeper gouges may exceed the film’s self-healing threshold. Many films also incorporate hydrophobic topcoats, repelling water and dirt, and UV inhibitors to prevent premature yellowing and degradation.

Debunking Common Paint Protection Film Misconceptions

The marketing landscape for paint protection film can sometimes create unrealistic expectations. It’s crucial to separate fact from fiction. While PPF offers substantial protection, it is not an invulnerable shield.

Vinyl Wrap and Paint Protection Film are Interchangeable

This is a significant misunderstanding. While both are films applied to vehicles, their composition, purpose, and protective capabilities differ vastly.

| Feature | Paint Protection Film (PPF) | Vinyl Wrap |

|---|---|---|

| Primary Purpose | Paint Protection (impacts, scratches, UV) | Aesthetic Modification (color/finish) |

| Material | Thermoplastic Polyurethane (TPU) | Polyvinyl Chloride (PVC) |

| Typical Thickness | ~6-12 mils (0.006-0.012 inches) | ~2-4 mils (0.002-0.004 inches) |

| Impact Resistance | High | Low to negligible |

| Self-Healing | Common in premium variants | Extremely rare / Generally not available |

| Optical Clarity | Typically crystal clear (though colored/matte exist) | Opaque (for color change) |

| Primary Application | Shielding original paint | Changing vehicle appearance |

A Perfectly Invisible Application Means No Seams

While installers strive for near-invisibility, paint protection film is a physical layer. Edges will exist. The visibility of these edges depends on the installation technique:

- Pre-Cut Kits: Generated by software and cut by a plotter, these kits are designed for specific vehicle panels. Modern pre-cut kits offer excellent coverage, often leaving a minimal 1/8th inch (approx. 3mm) gap from panel edges. This method minimizes the risk of cutting on the vehicle’s paint.

- Custom/Bulk Installation: Film is applied from a larger roll and trimmed directly on the vehicle. This can allow for wrapped edges, potentially hiding seams better on some panels. However, it carries an inherent risk of an installer accidentally scoring the paint if not executed with extreme precision and experience. This method may also involve removing vehicle components (lights, badges, handles), adding labor costs and potential risks of misalignment or damage to electrical components upon reinstallation.

For most applications, high-quality pre-cut kits offer an optimal balance of coverage, safety, and reduced edge visibility, minimizing the chances of lifting. Remember, it’s “Paint Protection Film,” not “Paint Perfection Film.”

My PPF Installation Will Be Absolutely Flawless

Vehicle paint protection film installation is an intricate, labor-intensive process. Even in highly controlled environments, microscopic airborne dust particles can become trapped.

- Environmental Factors: A dedicated, clean, well-lit installation bay with air filtration is crucial but doesn’t guarantee absolute perfection. Garages, non-enclosed shops, or dealership service bays are generally suboptimal.

- Minor Imperfections: Small bubbles or lift lines (where film was repositioned) are common immediately post-installation. Most water bubbles will evaporate within days or weeks, aided by heat. Persistent air bubbles may require a technician to address them with a fine needle.

- Pre-existing Paint Defects: PPF can magnify underlying paint flaws like dirt nibs, scratches, or sanding marks not addressed by paint correction prior to film application. Therefore, thorough paint preparation and correction are vital.

My Paint Protection Film Will Last Indefinitely.

No paint protection film is permanent. It serves as a sacrificial barrier. A realistic lifespan, even for top-tier films, is typically 5-7 years, extending to 10 years with meticulous care and favorable conditions. Over time, self -healing also decreases due to cumulative wear.

The manufacturer’s warranty, although often lengthy (eg 10 years), primarily covers production defects such as yellowing, bubbling or cracking under specific conditions. They rarely cover wear and tear when normal use, damage to road fragments or incorrect maintenance. Always review warranty terms carefully.

All PPF Installations and Materials Offer the Same Value.

Pricing for car paint protection film installation can vary significantly. This disparity reflects differences in:

- Film quality: premium brands are considerably investing in research and development, resulting in films with excellent clarity, durability and self -healing.

- Installation skill and experience: Highly qualified installation staff give higher rates due to their accuracy, knowledge and ability to handle complex installations with minimal shortcomings. Work Preparation: Comprehensive color correction before PPF application is necessary for optimal results and shine, which increases labor costs.

- Preparation Work: Comprehensive paint correction before PPF application is essential for optimal results and gloss, adding to the labor cost. Shops that skip or downplay this step may offer lower prices but compromise the final outcome.

- Overhead & Reputation: Established shops with proper facilities and a track record of quality often have higher operating costs reflected in their pricing. Fly-by-night operations can offer tempting prices, but lack long-term support or warranty.

Choosing the cheapest option can be a false economy that leads to Subpar installation, premature film failure or even damage to the color of the vehicle.

Conclusion

Color protection is a valuable technological advances to maintain the exterior of the vehicle. Its longevity and efficiency are naturally associated with the quality of the film material protection, installation accuracy, careful maintenance and the conditions of the environment that will last. Understanding science for TPU materials, self -healing top coats and nuances of the application allows vehicle owners to determine realistic expectations. By condemning ordinary myths and emphasizing the importance of professional installation and proper care, consumers can take informed decisions and ensure that their investment in the film for the protection of vehicles provides years of aesthetic protection and peace of mind. Finally, the PPF is well chosen and properly installed by proof of proactive car care.